Characteristics of Small Wood Pellet Mill

The roller turned flat die pellet mill, or small wood pellet mill, is one of our hottest products now. Roller turned flat die pellet mills cost a little bit more than die turned flat die pellet mill, but they are more cost effective and the capacity of roller turned small wood pellet mill are larger than the small sawdust pellet mill flat die.

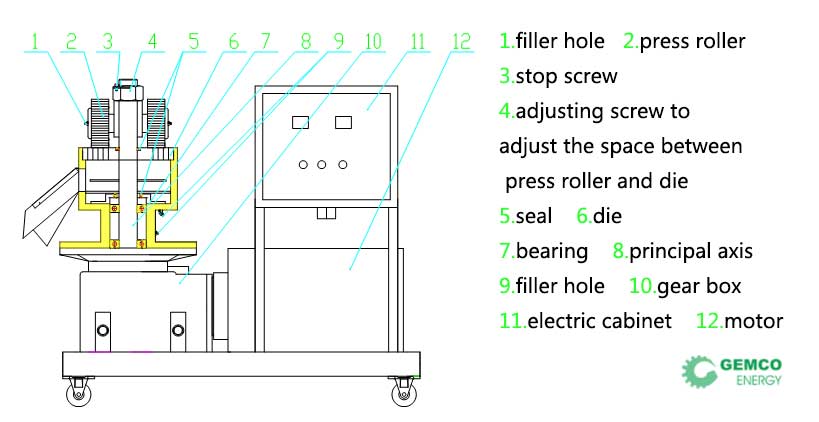

Small wood pellet mill structure and main parts

Small wood pellet mills, aka roller turned flat die pellet mills are of succinct structure. It takes only a small room and easy for installation and transportation. The structure and main parts are shown in the picture below:

Small wood pellet mill working principle

As shown in the picture above, the motor drives the principal axis through the gear box, the principal axis drives the press roller. After the raw materials are process to the suitable size and proper moisture, they are put into the feeding chamber, the biomass material layer are lying on the flat die evenly. The principal drives the roller tuning, the roller continuously press the raw material layer, and compress the materials into the pelletizing holes. The materials are shaped in the pellet mill flat die holes and then comes out in the shape of cylinder. The turning cutter cuts the pellets into the presupposed length, and the dump plate will send the pellets out.

Small wood pellet mill advantages

- Wide application. All kinds of biomass raw materials can be made into pellets no matter they are weed tree, pine, bamboo, peanut husk, rice husk, or straw. No addictive needed.

- The gear box adopts step gear-driven, the gears are made of superior alloy steel, the surface is treated by Carburizing and quenching, they are all fine ground. The gear features rotational stability, low noise, smooth rotation, slow temperature rise, long service life.

- The principal axis, roller, bearings are all of bigger size, can take more than a double load than the original load.

- Adopted large diameter roller, high yield. The pellets are well -shaped, even and high strength.

- The distribution of the pelletizing holes are changed. The contact area of the die and roller are larger. This prolongs the service life of die and roller. This tech has been patented.

- All the bearings are sealed. The dust can barely get into the box. The working environment of the bearings are improved, and thus the service life of the bearings are prolonged.

- All the shell are made of steel, the strength and toughness are improved, and the shell will never broken.

How to use a small wood pellet mill properly

- The moisture of the raw material should be kept in the range of 10-15%. If the moisture are higher than 15%, the material will slip between the die and roller, impact the pelletizing and capacity. If the moisture is lower than 10%, the friction between the die and roller will increase, this will harm the die and roller. This has bad influence on the capacity.

- The clearance between the die and roller also influence the effect of pelletizing. How to adjust the clearance between the die and the roller, please click here to check it.

- The new die should be ground before put in use. Matching 5kg fine sand, 16kg biomass raw material, like sawdust, 4kg waste machine oil, mixing them well. Put the material into the small wood pellet press to pelletzing for 40-60 minutes. Grind the machine until the pellets are loose. The operator should insure that more than 95% of the pelletizing holes can make pellets.

- When the operator uses the small wood pellet machine, the operator should fill all the pelletizing holes with biomass raw material which contains 12% oil. After using the roller turned flat die pellet mill, the operator should fill the pelletizing holes with materials with 1% oil to make sure that the pelletizing holes are not blocked.

- The operator should check the small wood pellet mill once a week to insure more than 95% pelletizing holes are not blocked.

- The clearance between feed plate and pellet mill die has influence on the capacity. If the clearance is to small, the raw material is difficult to get into the pelletizing holes. If the clearance is to big, the motor will overload and the machine may shut down.

- Cutter. The cutter under the small wood pellet mill die should keep a proper distance from the die. If they are too close, the powder will increase, and the capacity of the pellets will decrease. So the cutter should be adjust to a proper place.

- The small wood pellet press should be lubricate before using, and in the process of using it. The details about roller turned flat die pellet mill lubrication, please click here to check, thanks.

GEMCO provides all kinds of pellet mills, including small pellet mills and large scale pellet mills for industry. As the leading pellet mill manufacturer in China, GEMCO offers you the world class pellet mill machines and the most exclusive service. All of our pre-sales service including consultation, material test etc are free! Any needs, please leave messages. Get in touch today.