| Model | 150, 200, 230, 260, 300,400 |

|---|---|

| Power | single-phase 2.2 kw, triple-phase 3-30 kw |

| Capacity | 40-800 kg/h |

| Size | 2.5-12mm |

How do I work

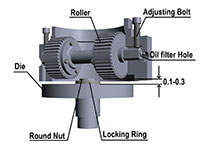

The pattern of pelletizing holes is directly related to the output of the pellet mill. A flat-die small pellet mill won't work better by just increasing or decreasing the quantity of the holes. Some pellet mill dies suppliers advertise their pellet mill dies as low energy consumption by downgrading the motor. But how to make up for the lack of power? They reduce the contact area of the die and the roller by decreasing the quantity of the pelletizing holes and the size of the roller. In this way, the energy consumption is lower indeed, but the output of the pellet mill get lower at the same time. As a result, the clients get zero benefits.

What can I do for you

GEMCO pellet mill die is made of superior alloy steel and both side of the die can be used to produce pellets. Our dies can process over 30 kinds of raw materials including wood, straw, grass, pineapple peel etc. And we can customized design the die for clients who have special needs.

We've got a lot questions about the thickness of pellet mill die from our clients, especially clients overseas. Here I should say, pellet mills won't work better by just increasing the thickness of the pellet mill dies, either. Pellets can be shaped smoothly or not is depending on the compression ratio. And the compression ratio depends on the thickness of the pellet mill die as well as the rotate speed of the pellet mill machine. In addition, different raw materials call for different compression ratios. So, the best way to choose a pellet mill die, is leave us a message about what is your material, and we will recommend the pellet mill die fits your need.