What can wood pellet making machine do for you?

GEMCO’s Sawdust Roller-Turned Pellet Mill processes a wide range of materials such as wood, pine, bamboo, peanut shells, straw, rice husks etc with no needing additives. This small pellet mill adopts large diameter press roller and all bearings are in a sealed structure to prevent dust entry, which improves the bearing work environment and prolong the bearing life. The contact area of the flat die and roller is increased by changing the form of the flat die mode, which greatly reduces the wear speed of the flat die and improves the flat die life (the patent has been applied). What’s more, the shell is made of steel, the strength and toughness are greatly enhanced, no shell fracture phenomenon will occur. In that way the mill can produce more pellets. These pellets are hard, high-density, high-strength while their surface are bright and clean.

Electric Motor-driven Type Wood Press Machine(Model B)

| Type | Power (kw) | Output (kg/h) | Weight (kg) | Package size (mm) |

|---|---|---|---|---|

| ZLSP 200B | 7.5 | 80-120 | 215/245 | 950x450x1050 |

| ZLSP 300B | 22 | 250-350 | 540/575 | 1350x750x1400 |

| ZLSP 400B | 30 | 350-450 | 770/810 | 1400x800x1450 |

| ZLSP 420B | 37+ 0.37 | 400-600 | 1050/1100 |

1680x650x1500 550x450x1100 |

Diesel Engine-driven Type Small Wood Pellet Machine(Model A)

| Type | Power (kw) | Output (kg/h) | Weight (kg) | Package size (mm) |

|---|---|---|---|---|

| ZLSP 200A | 15 | 80-120 | 320/350 | 1460x950x1100 |

| ZLSP 300A | 41 | 250-350 | 850/890 | 2480x700x1100 |

| ZLSP 400A | 55 | 350-450 | 1010/1050 | 2600x800x1300 |

| ZLSP 420A | 62 | 400-600 | 1200/1250 | 2640x700x1500 |

How do small wood pellet machine work?

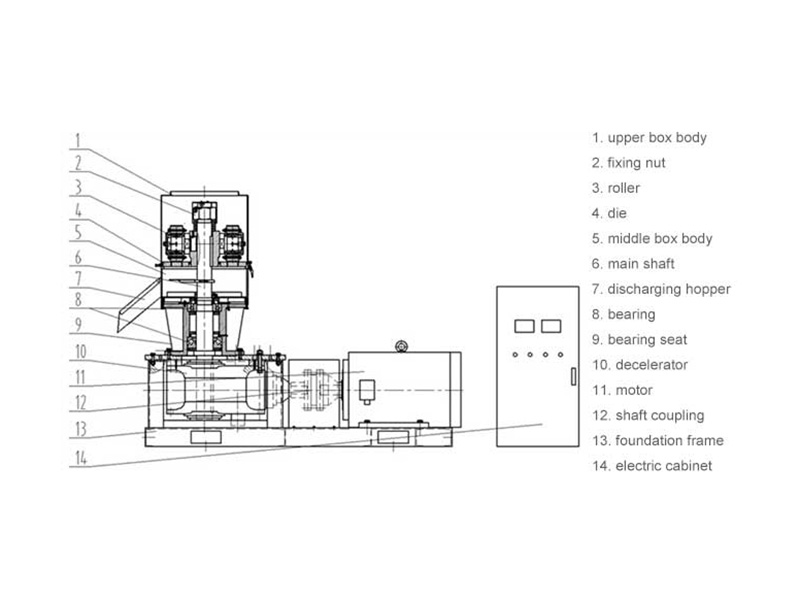

Sawdust Roller-Turned Pellet Mill works like the Sawdust Die-Turned Pellet Mill but its roller rolls above the grindling disc while the die keeps steady. The main shaft, main shaft bearing, roller and roller bearing are all increase in size so that they can easily bear more than a double payload compared to the other kinds of pellet machines. The die compression ratio can be selected as per the specific material. Die service life can be prolonged if both sides of the die are used. Roller-Turned Pellet Mill creates stronger pressure on the material layer than the die-turned one, so it is especially suitable for softwood and hardwood processing. Otherwise, making softwood pellets and hardwood pellets.

Wood pelletizing machine advantages

- Small size and capacity, suitable for making small scale pellets at home or on farm.

- Simple structure design, easy to operate.

- High quality of flat die and press roller, long service life.

- Multiple choice of power: PTO (power taken off) type, gasoline engine, electric motor and diesel engine.

Sawdust Roller-Turned Pellet Mill is profession on making biomass pellets. More information, if you want to know more information, just send us a message, and we will answer you ASAP.