What can mobile pellet plant do for you?

MPL 300 Biomass Mobile Pellet Plant can process any kind of biomass materials including wood fiber, like peanut shell, bagasse, castor shell, straw, sawdust, coffee grounds, rice husk, sunflower shell, cotton stalk, tobacco residue, leaf mustard stalk, bamboo, jute residue, tea residue, wheat-straw, palm shell, bean shell, coconut shell, dregs of decoction, and wood waste, etc.

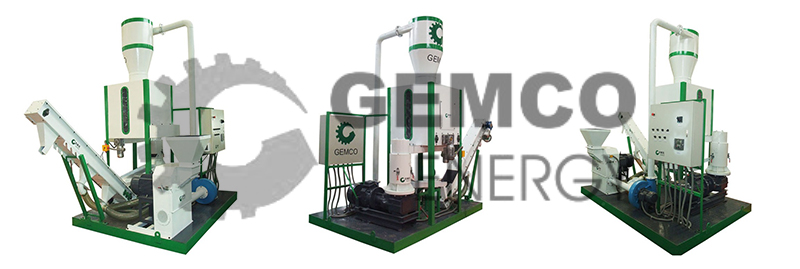

This mobile plant is convenient to move and due to the delicate design, the multifunctional plant is small and favorable for transportation.

Biomass Mobile Pellet Plant

The pellets produced by can be widely used for heating or in electricity industries as biofuel. If you are intended to join the pellet business, MPL 300 Biomass Mobile Pellet Plant can be your best partners who make money and save costs at the same time. Contact us now and start to make your own pellets!

Mobile pellet plant we offer

| Type Wood pellet(6mm-10mm) | Capacity (Hp) | Output (kg/hr) | Weight (kg) | Package size (mm) |

|---|---|---|---|---|

| MPL400R | 41.44 | 250-350 | 2300 | 3500x1960x3500 |

| MPL400R | 49.44 | 350-450 | 2400 | 3500x1960x3500 |

| MPL420R | 56.81 | 400-600 | 2500 | 3500x1960x3500 |

How do mobile pellet plant work?

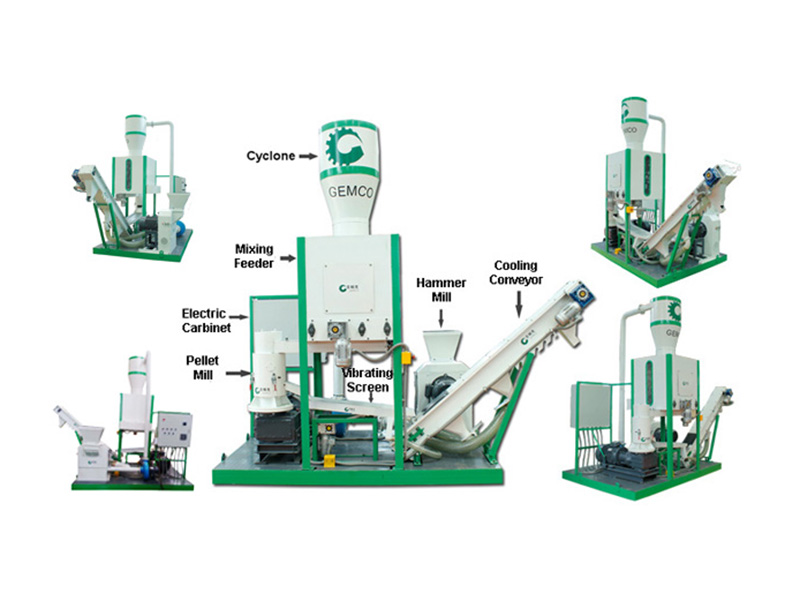

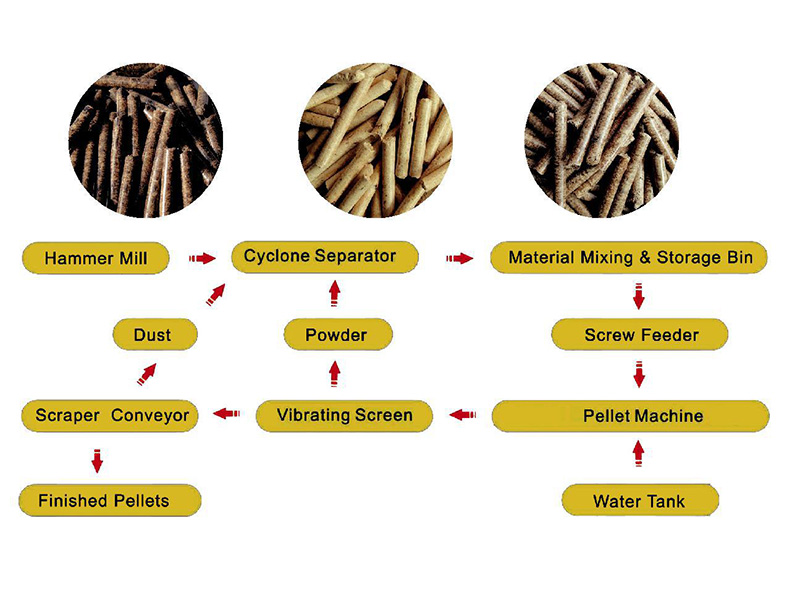

With the delicate structure design, the necessary processing equipments are arranged in one complete plant, primarily consisting of hammer mill, cyclone separator, bin, screw conveyor, pellet mill, vibrating screen, scraper conveyor, electric cabinet, and foundation frame. The monile pellet plant integrates the processing functions of crushing, pelletizing, cooling, transporting, etc, improves the working efficiency remarkably and lowers your pellets production costs. One operator can manage the operation of this whole mobile pellertizing equipment by simple adjusting the operation buttons, which reduces your labor cost efficiently.

All of the electrical parts of MPL 300 Biomass Mobile Pellet Plant are made by Schneider. They are so reliable that ensure the continuous production of the pellet plant. The frequency conversion motors installed in the feeder can control the screw conveyor to adjust the feeding speed effectively.

Mobile pellet plant advantages

-

Compact structure.

Mobile small integrated wood pellet plant takes smaller room and it is more convenient for movement and transportation. We can set wheels for mobile small pellet plant if you need, which make it more easy to move around. -

Small footprint.

The maximum height of this mobile pelletizing equipment has been reduced, it takes only a little room and it is more convenient for transportation. Wide Application.

Mobile small pellet plant can process all kinds of biomass materials including wood fiber, such as peanut bagasse, shell, straw, sawdust, bamboo, castor shell, coffee grounds, rice husk, wheat-straw, cotton stalk, sunflower shell, tobacco residue, dregs of decoction, leaf mustard stalk, jute residue, tea residue, wood waste, bean shell, coconut shell, and palm shell, etc. -

Fall Automatic.

Mobile pellet plant is full-automatic because of its PLC control system. Just push one button, this mobile small pellet plant can make pellets for you in pack. -

Reliable electrical parts.

All the electrical parts in this mobile small pellet plant are from the Schneider, they are in reliable quality. To ensure continuous production, the frequency conversion motors are installed in the feeder and screw conveyor to adjust the feeding speed.