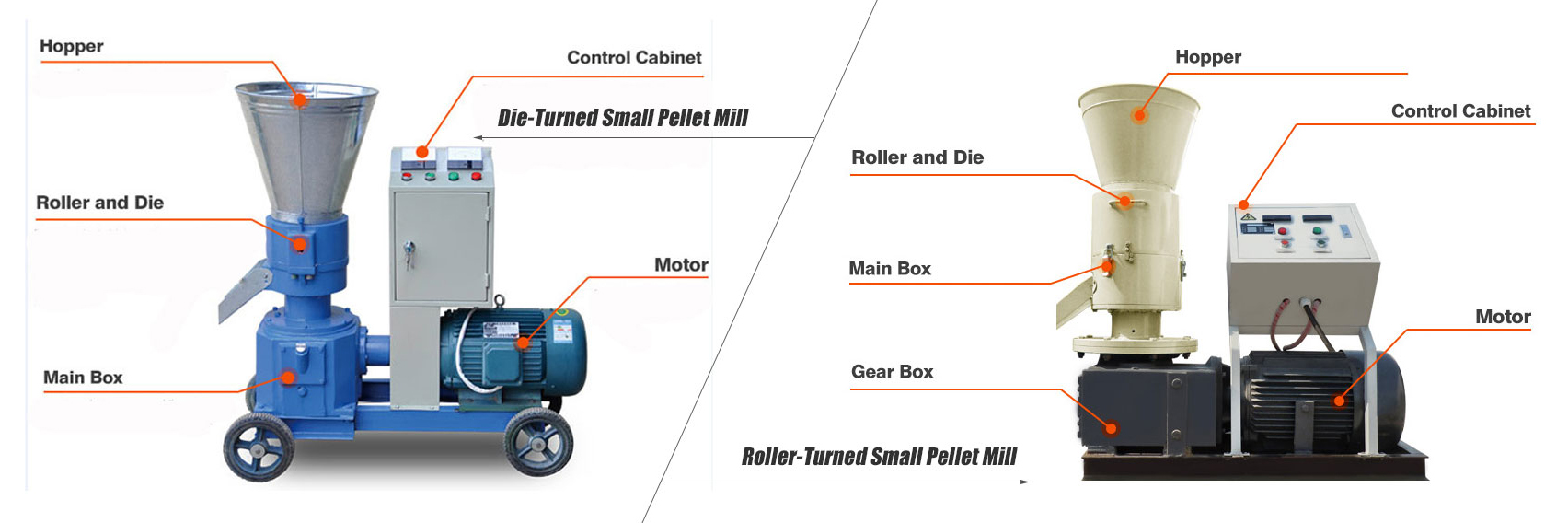

The flat-die pellet mill is mainly composed of motor, gear box, shafts, die, roller, feed hopper, cutter and disc of throwing pellet. As the raw materials are pressed and shaped between the die and the roller, they become the core parts of a small pellet mill. In the pelletizing process, great pressure is generated from the rotation of the die and the roller, so these two parts are especially vulnerable. Not only GEMCO, every pellet mill has this soft spot no matter which brand it is.

- we should use the pellet mill in strict accordance with the product label instructions.

- we should do regular scheduled maintenance on the wearing parts.

- And even if we've done both perfectly, pellet press parts have certain service life, when the pellet machine parts' serving life come to an end, we should replace them with pellet mill spare parts.

So there comes the question: how to select spare parts, why GEMCO spares, and what kind of wood pellet mill parts can be offered by GEMCO? I can give you the answers right now.

Why GEMCO parts

Choose spare parts according to the model of your pellet machine. Good spare parts are tough and cost-saving, they have a long service life and do the machine no harm. GEMCO spare parts have good quality and reputation. All spare parts are designed and manufactured carefully. To guarantee they can replace the original ones directly, we've prepared a large parts inventory for each model we produced.

What's more, GEMCO pellet mill spares also have the following advantages.

- Hard. GEMCO pellet mill die and roller are all made from high quality alloy steel with a hardness of 55-60HRC.

- Wear-resisting. GEMCO pellet mill die and roller are made from 40Cr instead of 45#, which has a widespread use among pellet mill parts suppliers around the world.

- Flexible. The pelletizing holes of GEMCO pellet mill die have the aperture of Ø2.5-Ø10. Clients can choose different dies according to the materials for best pelletizing results. And in addition, both side of GEMCO pellet mill die can be used, make sure you've put the die into full use.

- Patent. The structure of GEMCO pelletizing hole is patent. To get the compression ratios, our R&D team has paid a great effort.

Wearing Parts we offer

Spare Parts For model ZLSP-D

| Parts | Model | Installation site | ||||||

|---|---|---|---|---|---|---|---|---|

| 120 | 150 | 200 | 230 | 260 | 300 | |||

| Bearing | 6203RZ | 6204RZ | 6205RZ | 6206RZ | 6306RZ | Roller | ||

| Bearing | 6206 | 6206 | 6208 | 6209 | 6312 | 6312 | Main shaft | |

| Bearing | 30207 | 30207 | 30309 | 32309 | 30312 | 32313 | Main shaft | |

| Bearing | 6204 | 6204 | 6206 | 6307 | 6305 | 6207 | Gear shaft | |

| Bearing | 30205 | 30205 | 30207 | 31309 | 30309 | 31309 | Gear shaft | |

| Bearing | 30209 | 30209 | Gear shaft | |||||

| Bearing | 6207RZ | Roller | ||||||

| Grease seal | 28*50*10 | 28*50*10 | 42*70*11 | 47*84*12 | 58*90*12 | 55*90*12 | Gear shaft | |

| Grease seal | Felt retainer | Roller | ||||||

| Grease seal | Felt retainer | Main shaft | ||||||

| Washer | 80 | 80 | 105 | 105 | 150 | 150 | Coupling | |

| Roller | Upper box body | |||||||

| Mold | Upper box body | |||||||

Spare Parts For model ZLSP-R

| Parts | Model | Installation Site | ||

|---|---|---|---|---|

| 200 | 300 | 400 | ||

| Bearing | 32310 | 32316 | 32318 | Main shaft |

| Bearing | 6310 | 6316 | 6318 | Main shaft |

| Bearing | NJ207E | NJ211E | NJ213E | Roller |

| Grease seal | 42*62*8 | 60*80*8 | 70*90*10 | Die |

| Grease seal | 45*65*8 | 75*95*10 | 85*105*10 | Dust cover for the main shaft |

| Dustproof | Felt retainer |

60*3.55 O-shaped |

70*3.55 O-shaped |

Roller |

| Dustproof | Felt retainer | Felt retainer | Felt retainer | Main shaft |

| Roller | Upper box body | |||

| Die | Upper box body | |||

After reading the information above, you may have got a overview about GEMCO pellet mill parts already. Check your pellet mill, see if there is any spare parts you want to update. If the answer is yes, contact us for replacement and backup parts today!