How to Adjust the Clearance Between Pellet Mill Dies and Rollers

No matter what kind of pellet mills you have purchased, there is a problems that you can’t ignore. That is how to adjust the clearance between pellet mill dies and rollers. Small pellet mill, generally flat die pellet mill, can be divided into the die turned type and the roller turned type.

Die turned pellet machine and roller turned pellet press

Die turned small pellet machine makes pellets by the stress produced by the steady roller and turning die. The roller presses the material layer while the die turns, then the material is pressed into the pelletizing hole. The material is heated and shaped in the pellet press holes and after a while, the well-shaped pellets come out of the pellet mill machine.

The roller turned pellet mill press, makes pellets with a steady die and a turned roller. Roller turned small pellet mill has a roller rolls above the material layer, and because of the pressure generated by the dead weight of the roller and the motor, the material is pressed into the pellet mill die holes. Roller turned pellet mill can process harder materials than die turned pellet machine. If your material is sawdust, straw or grass, all kinds of small pellet mills can make quality wood pellets with smooth surface. But if you want to make softwood or hardwood pellets which contain more calories, the roller turned pellet mill is a better chice.

But both types of small pellets need proper clearance between die and roller. If not, there will be no pellets coming out.

Requirement of adjusting the clearance between die and rollers

Clearance between die and roller has great influence on pellet quality. The best range of clearance remains 0.1mm - 0.3mm. The clearance adjustment depends on specific materials. When the clearance is over 0.3mm, the material builds up a thick layer on die, so the pellet capacity will be reduced greatly. When the clearance is less than 0.1mm, it will aggravate the abrasive wear between die and rollers, causing the service life shortened.

How to adjust the clearance of roller-driving pellet mill ZLSP-R

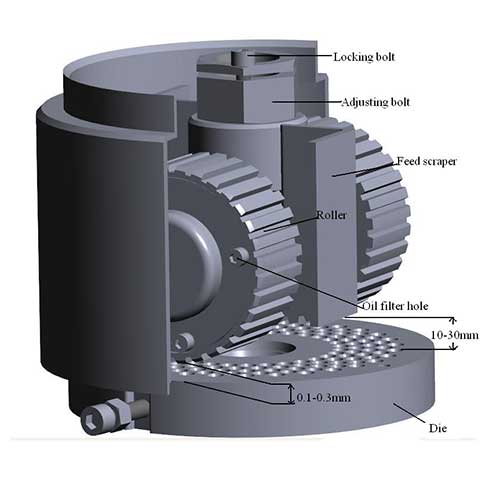

Roller-driving pellet mill ZLSP-R is roller turned pellet machine as we mentioned above. Adjust before operation: As shown in the following drawing, release the locking bolt before feeding material to machine. Screw the adjusting bolt clockwise till it cannot be screwed by hands, and screw the adjusting bolt anticlockwise 15°-30°. Then tighten the locking bolt at last.

How to adjust clearance between feed scraper and die of pellet mill ZLSP-R

Adjust before operation: the clearance between feed scraper and flat die will greatly influences the output. If the clearance is too small, the material is hard to squeeze into the die holes, which would result in low output and more powdery products. If the space is too large, the motor will be overload or even burn out. The suitable distance between feed scraper and die is 10-30mm.

How to adjust the clearance of pellet mill ZLSP-D

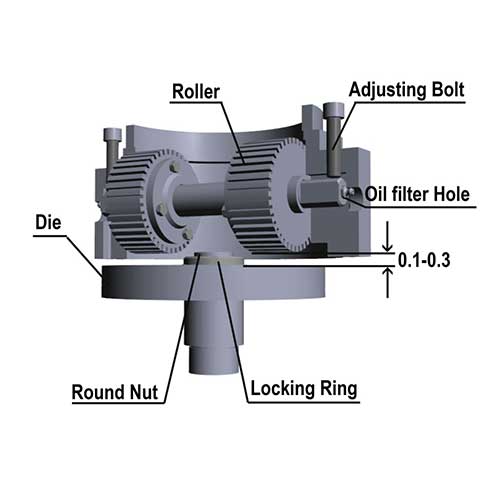

Pellet mill ZLSP-D is die turned pellet mill. As shown in the following drawing. Shortly after starting the mill, feed a small amount of material and turn the adjusting bolts on both sides of the roller evenly until the die drives the roller to run. Feed materials gradually and adjust bolts according to pellet quality and quantity.

Not just small pellet mill, if you own a small pellet plant or a small pellet production line, or even a complete wood pellet line, the clearance of the die and roller should be adjust to a proper distance. Not only that, we can also offer help. We can pre-set the clearance for you and if you are setting a complete biomass pellet line, we can send professional staff to help you with all the debugging.

GEMCO has already have a long history of designing and manufacturing best small pellet mill and have won good reputation both domestic and abroad. So we are pretty experienced in biomass pellet machine. We offer other machines you may need in making pellets including integrated cooling screen for pellets, wood chipper, airflow dryer, pellet packing machine etc. And we offer service including free consultation, free raw material test and precise budget and customized design. We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!