how to make wood pellets

If you've opened this free pellet mill guide, I assume that you may have got some knowledge about wood pellets already. Wood pellets were introduced to people in the 1970s. At that time, some company began to make wood pellets as a kind of fuel source. But with the low price of the fossil fuels, the development of wood pellets market was not looked upon favorably.

Until 21st century, people found that the environment has become a huge problem which affected our daily life, and the unsustainable use of the fossil fuels might dry our fuel source out in the foreseeable future. As more and more countries put the energy saving and emission reduction on the desk, wood pellets became a high-profile renewable energy source.

The market demand of wood pellets grew so rapidly, and there were even supply problems happened for several times. Now, wood pellets are still an important energy source for power generating and home heating. Some farseeing clients of us, who entered this business with GEMCO pellet mill machines, have already dug out their first barrel.

So, in this article of our free pellet mill guide, we'll talk about how to make wood pellets, but not make pellets at home by some homemade equipment. In the wood pellet making process, there are certain professional machines you may need. Here is the list:

| Size Reduction | Chippers/Shredders, Hammer Mills |

|---|---|

| Material Transportation | Fans, Cyclone Separators and Screw Augers |

| Drying | Rotary/Drum Dryers, Pipe Dryers |

| Mixing | Batch Mixers |

| Conditioning | Water and Steam Addition, Binders |

| Pellet Production | Round and Flat Die Pellet Mills |

| Sieving | Removing Fines |

| Cooling | Counter Flow Coolers |

| Pellet Transportation | Bucket Elevators |

| Bagging and Storage | Bags, Sacks and Silos |

Except the clients who have their own ways to get enough sawdust or wood shavings, most of our clients are using whole trees, short wood, wood chips, or woody biomass. This kind of materials are always large in size or contain a lot of impurities, thus, they need to be sieved and cut for several times to ensure the quality of the pellets made of them.

-

Size reduction

No matter what the raw material you use, the size can not be bigger than the diameter of the pelletizing holes. Check the size of the pelletizing holes of your pellet machine, then you can get the idea of how big can your materials be. When you process the raw materials, you may need a wood chipper, which can cut the logs, branches and bark into small pieces. But if you want to make wood shavings or something similar small, you may cut this step off.

-

Drying

For large sale wood pellets production, the materials should be dried after initial size reduction. To make quality wood pellets, the moisture content of the material should be kept in the range of 8%-12%. There are two kinds of dryer can be set in the wood pellet plant, the airflow dryer and the drum dryer, or you can call it rotary drum dryer. The airflow dryer is for small pellet plant, while the drum dryer for large pellet plant or complete biomass pellet line can dry more materials at one time. Both of them are efficient. More information, please leave us messages and get a quote. -

Sieving

Raw materials can't be put into process without sieving. Impurities like metal particles and little stones can cause serious problems to the pellet mills. The roller and die will be wear out pretty quick if the hard objects are not fully removed from the materials. Large scale pellet production can use de-stoner or magnetic separator. -

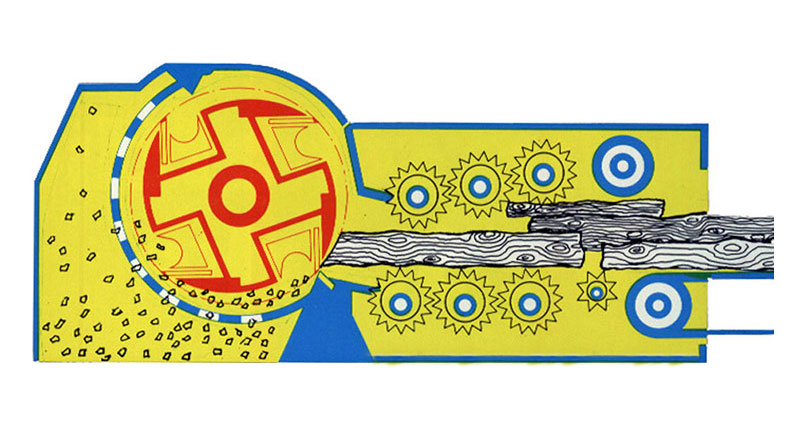

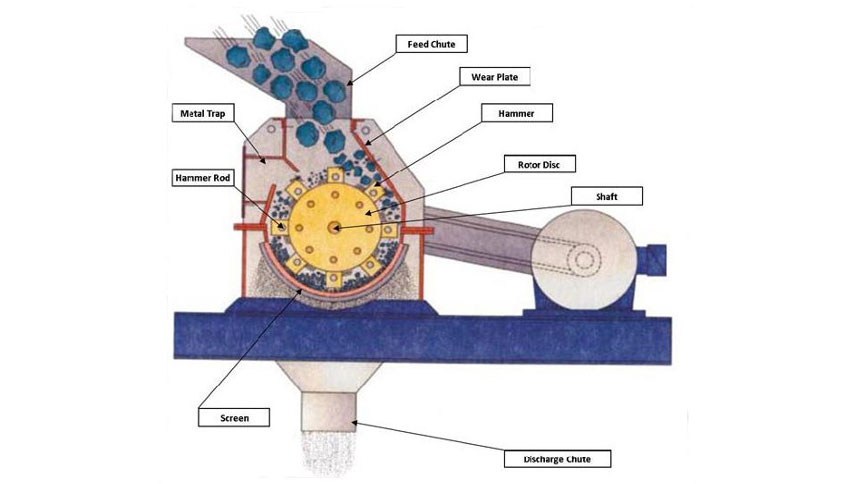

Grinding

Normally, the diameter of pelletizing holes is from 2.5mm to 12mm. The die for making wood pellets usually has the 5mm pelletizing holes. When the materials are put into the pellet machine, they should be smaller enough to get though the pelletizing holes, so the size of the materials can't be bigger than the die holes. Although the wood chipper has reduced the size of materials, the materials still can range from 1cm-4cm. Thus, we need a hammer mill to crush the materials and reduce the size again.

-

Pelletizing

After the steps above, the materials are all set. Check whether the safety protection measure is completed or not, then you can start to make wood pellets. GEMCO offer both large scale pellet mill and small pellet mill, but on my site, I mainly recommend small pellet mill machine and small pellet plant to people who are new to this business. A flat-die pellet mill usually has the capacity of 200-800kg/h, but if you need the pellet mill which has a capacity of 1ton/h, leave us a message, we can offer prices, budget, and a customized plan anyway.

-

Cooling

After the pelletizing process, the pellets comes out from the pellet mill. Those pellets are hot and soft a this right time, and they are easily to be deformed. They should be cooled to the proper temperature. In this way, they can be smooth and hard. To cool the pellets, we offer counterflow cooler. Counterflow cooler can cool the pellets very fast, which can do great favour for pellets packing and installing. -

Final sieving

If the wood pellets you made is for commercial, you may need to separate the well shaped pellets from the pellets that didn't reach the standard. For this step, the suitable machine is a vibrating screen. But I haven't post the screen on this site. If you need one, leave us messages, we will send you the price and other information you need immediately.

Now we've learnt something of how to make wood pellets, but this is mainly about how to make commercial pellets. If you want to make wood pellets for home, the process will be much easier. Just a small pellet mill can do all the work. There are already many information on the Internet, but I still want to share what I know about pellets to everyone, thanks for reading. Any questions, leave me messages, and you will get answers directly from our professional staff and the solution will be posted in our free pellet mill guide or FAQs!