how to make straw pellets

Straw is an agricultural by-product, it makes up about half of the yield of cereal plants such as rice, corn and wheat etc. Compressing straw into pellets is a modern way to utilize straw resources. Straw pellets can be used as fuel, animal bedding and animal feeds etc. Considering the ready availability of raw materials, making straw pellets has strong economic benefits.

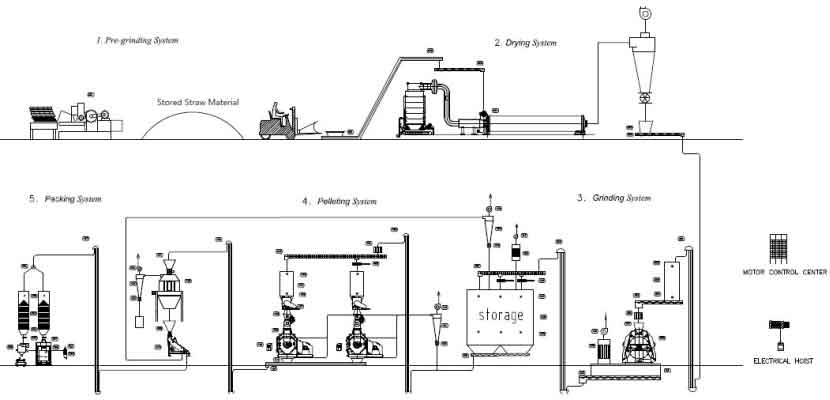

However, the straw contains many different compositions, so we put a step-by-step process here to guide people who have troubles with straw pellets making.

-

Pre-treatment

The harvested straw usually mixed with many impurities such as little stones, dusts, metal debris and plastics etc. These impurities are very likely to cause damage to the pellet making machine, so they must be removed or screened out before you put the straw to a pellet mill. -

Crushing

Straw is in different sizes, it may not suit the pellet mill, so it should be crushed into chips or powder. In this process, you may need a hammer mill, but other ways like cutting and chopping can also help you get the materials in proper size. -

Drying

It is important that you dry the materials before put them into pellet mills, if the materials are too wet, they won’t be made into pellets successfully. The moisture should be controlled within a range of 10%-18%. In this process, you may need a airflow dryer or a drum dryer in your pellet line, these two kinds of dryer can all help you control the moisture of raw materials precisely. -

Adjusting

GEMCO small pellet mill can make pellets perfectly without any additives. But if you use additives like adhesive properly, you can control the hardness of straw, which can increase the yield and quality of pellets. Pelletizing

Put the raw materials into the feeder house of your pellet mill and start to make your own pellets! You can choose GEMCO ZLSP die-turned sawdust pellet mill, roller-turned pellet mill or other kinds of all set pellet plants according to your specific situation such as target yield, site, local environmental protection standard etc. Any question, please contact us, leave a message below, we will reply you ASAP. -

Cooling and Screening

The pellets should be cooled down to keep in shape after pelletizing. GEMCO counterflow cooler can cool the pellets and screen out the unformed pellets. Or, GEMCO MPL 300 Biomass Mobile Pellet Plant can do all the work in the pellet making process including re-process the unformed materials. -

Packing

After the pellets cooling process, you may want to package the pellets for sale or household. GEMCO offer our pellet packing machine, or you can bagging them yourself if the quantity is small.

Straw pellets are of wide application, high economic value and big market demand. If you need more information about straw pellets and straw pellets making, leave us a message below, we will give you a satisfactory answer once the message is received.