troubleshooting common small wood pellet mill problems. part2

This article will be a series about how to solve the pellet mill problems. First of all, let's be clear that these solutions are especially given to the small pellet mill, or you can say, wood pellet mill, and the pellet machine must be flat-die type. If you have a troubled ring-die pellet press, we may talk about it later in other series, but not here.

This series include three parts. In the first part, we will know about the inner structure of both die-turned and roller- turned small pellet mill. And I will make a brief about how does the wood pellet machine work and how are wood pellets made. In the second part, we will learn how are the crucial parts of the small pellet mill broken, and how to maintain the wearing parts. In the third part, we will talk about pellets, how to make wood pellets and why the pellet mill won't work well.

The wearing parts of small pellet mill

Generally speaking, the most vulnerable parts of the flat-die small pellet mill are the die and the roller. Because of the pressure between them, they are easy to get damaged. But this is not the only two parts wear quickly. In fact, electric parts, bearings, grease seals, belts etc. can be broken soon if they are not used properly.

In GEMCO's circumstance, the small pellet mill's characteristics are fully detailed in the brochure. Follow the directions and the parts can serve a long time. But if the parts wear, we can provide spare parts according to the model of your pellet machine. Our spare parts are all certificated with CE and ISO9000, please feel free to contact us if you need them.

Here are the charts of the wearing parts.

Main wearing part list of model ZLSP-D

| Parts | Model | Qty | Installation site | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 120 | 150 | 200 | 230 | 260 | 300 | ||||

| Bearing | 6203RZ | 6204RZ | 6205RZ | 6206RZ | 6306RZ | 4pcs | Roller | ||

| Bearing | 6206 | 6206 | 6208 | 6209 | 6312 | 6312 | 1pc | Main shaft | |

| Bearing | 30207 | 30207 | 30309 | 32309 | 30312 | 32313 | 1pc | Main shaft | |

| Bearing | 6204 | 6204 | 6206 | 6307 | 6305 | 6207 | 1pc | Gear shaft | |

| Bearing | 30205 | 30205 | 30207 | 31309 | 30309 | 31309 | 1pc | Gear shaft | |

| Bearing | 30209 | 30209 | 1pc | Gear shaft | |||||

| Bearing | 6207RZ | 6pcs | Roller | ||||||

| Grease seal | 28*50*10 | 28*50*10 | 42*70*11 | 47*84*12 | 58*90*12 | 55*90*12 | 1pc | Gear shaft | |

| Grease seal | Felt retainer | 2pcs | Roller | ||||||

| Grease seal | Felt retainer | 1pc | Main shaft | ||||||

| Washer | 80 | 80 | 105 | 105 | 150 | 150 | 1pc | Coupling | |

| Roller | 1set | Upper box body | |||||||

| Mold | 1pc | Upper box body | |||||||

Main wearing part list of model ZLSP-R

| Parts | Model | Qty | Installation Site | ||

|---|---|---|---|---|---|

| 200 | 300 | 400 | |||

| Bearing | 32310 | 32316 | 32318 | 1pc | Main shaft |

| Bearing | 6310 | 6316 | 6318 | 1pc | Main shaft |

| Bearing | NJ207E | NJ211E | NJ213E | 4pcs | Roller |

| Grease seal | 42*62*8 | 60*80*8 | 70*90*10 | 1pc | Die |

| Grease seal | 45*65*8 | 75*95*10 | 85*105*10 | 1pc | Dust cover for the main shaft |

| Dustproof | Felt retainer |

60*3.55 O-shaped |

70*3.55 O-shaped |

2pcs | Roller |

| Dustproof | Felt retainer | Felt retainer | Felt retainer | 1pc | Main shaft |

| Roller | 1set | Upper box body | |||

| Die | 1pc | Upper box body | |||

How to maintain the wearing parts

Here we talk about why the parts get damaged. By know the reason, we can keep the parts from improper operations and save the cost of changing parts.

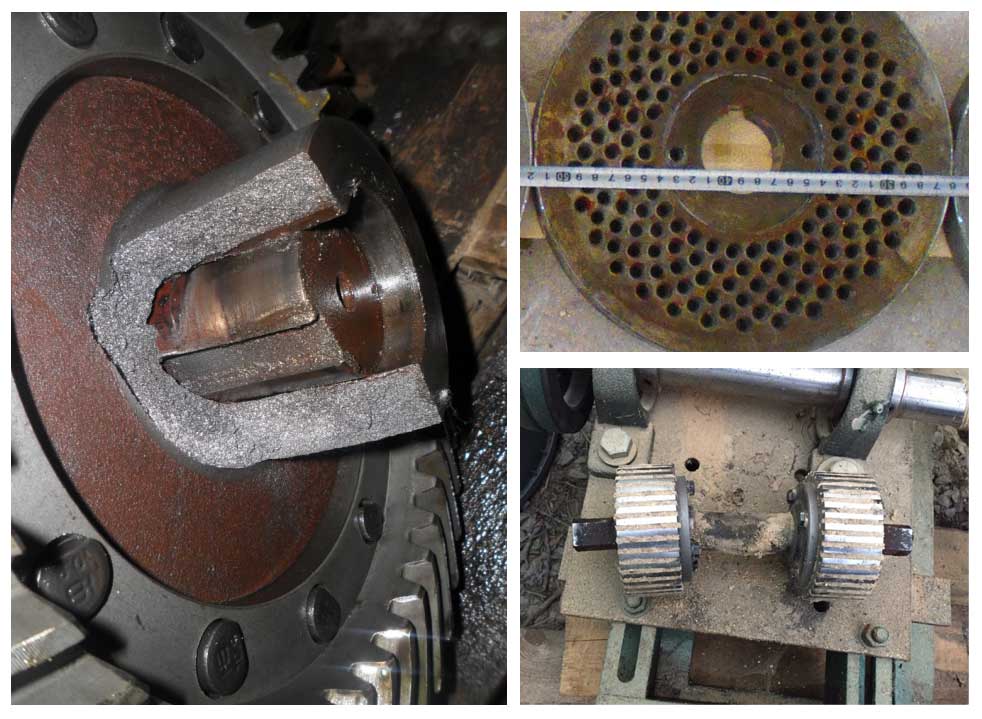

The roller

| Problems | Causes | Solutions |

|---|---|---|

| Why the roller shaft gets deformed or fractured? |

|

|

| Why the bearings of the roller get damaged? |

|

|

| Why the roller shell wear quikly? |

|

|

The die

| Problems | Causes | Solutions |

|---|---|---|

| Why the die broke up? |

|

|

| Why the die wears so quickly? And why there are no pellets are produced? |

|

|

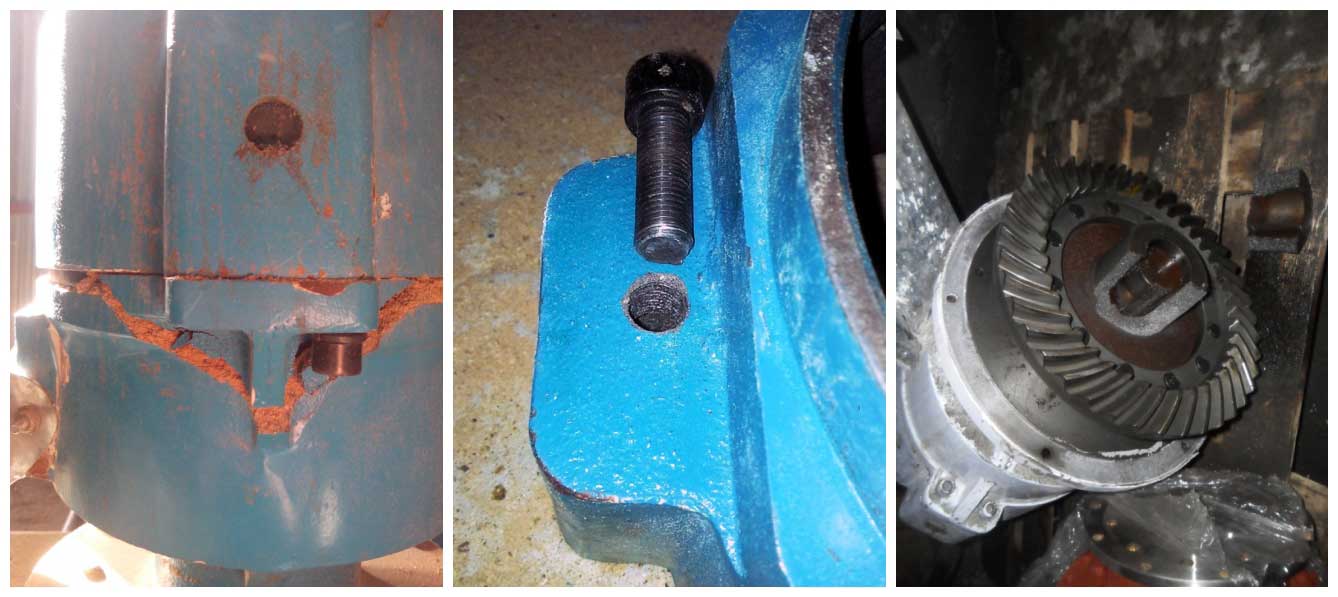

The box body

| Problems | Causes | Solutions |

|---|---|---|

| Why the box body broke? |

|

|

| The box body can't be strengthening because of the fastening thread damage. |

|

|

| Pinion gear damage. |

|

|

Usually, service life of a die is 300-500 hours under normal running condition. Most of the dies can be used on both sides. As for the roller, service life is also 300-500 hours under normal running condition. It is recommended to replace roller and die at the same time. And first of all, pellet mill should be used in the proper way following the directions. No company will take responsibility for the loss or damage directly or indirectly caused by improper operations.

GEMCO provide quality pellet mills and plants. And we want to be helpful at the same time. If you're interested in our products, please leave us messages and get a quote. If you already have pellet mills, we are happy to solve your problems and also, we offer ISO spare parts. The other part of the series will be posted next week. If there is any trouble you are experiencing and I haven't talked about, leave a message, I'll give answers in the FAQ in the following days.