troubleshooting common small wood pellet mill problems. part1

This article will be a series about how to solve the pellet mill problems. First of all, let's be clear that these solutions are especially given to the small pellet mill, or you can say, wood pellet mill, and the pellet machine must be flat-die type. If you have a troubled ring-die pellet press, we may talk about it later in other series, but not here.

This series include three parts. In the first part, we will know about the inner structure of both die-turned and roller- turned small pellet mill. And I will make a brief about how does the wood pellet machine work and how are wood pellets made. In the second part, we will learn how are the crucial parts of the small pellet mill broken, and how to maintain the crucial parts. In the third part, we will talk about pellets, how to make wood pellets and why the pellet mill won't work well.

The inner structure of small pellet mill

To solve problems about small pellet mill, we'd better know some more about this kind of machine. By learning the inner structure of small pellet mill, we can understand the solutions easier. GEMCO small pellet mill can be divided into two types, the die-turned type and the roller-turned type. If you've had other brand pellet mill, don't worry, as long as it is a flat-die pellet mill, these solutions work.

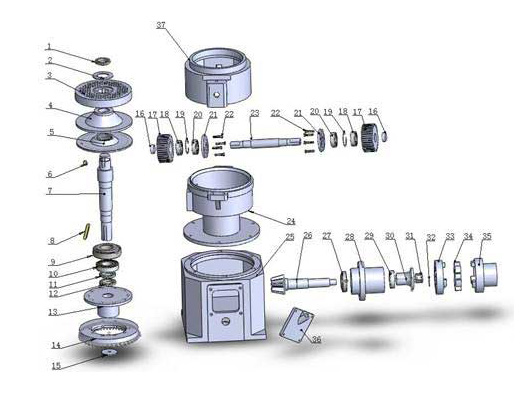

Check the charts below, and get to know every part of a small pellet mill. (I'm sorry that the chart is not easy to read with the picture. I will figure out a way to improve the readability and correct the typesetting.)

Structure and main parts of model ZLSP-D

| Item | Description | Qty | Item | Description | Qty |

|---|---|---|---|---|---|

| 1 | Round Nut | 1 | 20 | Bearing | 2 |

| 2 | Flat Washer | 1 | 21 | Bearing Cover of Roller | 2 |

| 3 | Die | 1 | 22 | Hex Bolt | 8 |

| 4 | Disc of Throwing pellet | 1 | 23 | Roller Shaft | 1 |

| 5 | Dust Cover of Main Shaft | 1 | 24 | Shaft Box | 1 |

| 6 | Flat Key of Type A | 1 | 25 | Gear Box | 1 |

| 7 | Main Shaft | 1 | 26 | Gear Shaft | 1 |

| 8 | Flat Key | 1 | 27 | Bearing | 1 |

| 9/10 | Bearing | 1 | 28 | Pinion Seat | 1 |

| 11 | Round Nut | 1 | 29 | Bearing | 1 |

| 12 | Round Nut | 1 | 30 | Splined Sleeve | 1 |

| 13 | Big Gear Seat | 1 | 31 | Castle Nut | 1 |

| 14 | Big Gear | 1 | 32 | Cotter Pin | 1 |

| 15 | Washer | 1 | 33 | Passive Coupling | 1 |

| 16 | Check Ring | 2 | 34 | Elastic Cushion | 1 |

| 17 | Roller | 2 | 35 | Active Coupling | 1 |

| 18 | Bearing | 2 | 36 | Cover of Observation Hole | 1 |

| 19 | Washer | 2 | 37 | Upper Box Body | 1 |

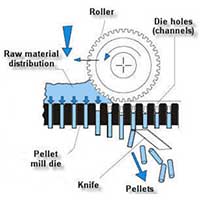

From this chart, we can figure out that, the die and the roller is crucial to a small flat-die pellet mill. The motor drives the gear, and the gear drives the main shaft, then the main shaft drives the die to roll below the roller. The raw materials are pressed between the die and the roller, and shaped in the die holes. So these tow parts have to generate a lot of pressure. As a consequence, they are easy to broke. All of other parts are serving the these two so that the wood pellet machine can press the wood chips or sawdust into density pellets.

From this chart, we can figure out that, the die and the roller is crucial to a small flat-die pellet mill. The motor drives the gear, and the gear drives the main shaft, then the main shaft drives the die to roll below the roller. The raw materials are pressed between the die and the roller, and shaped in the die holes. So these tow parts have to generate a lot of pressure. As a consequence, they are easy to broke. All of other parts are serving the these two so that the wood pellet machine can press the wood chips or sawdust into density pellets.

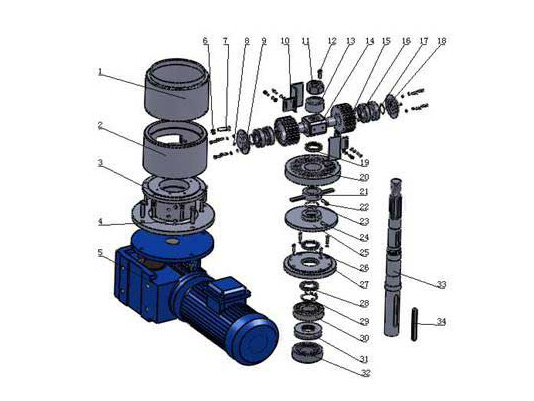

Structure and main parts of model ZLSP-R

| Item | Description | Qty | Item | Description | Qty |

|---|---|---|---|---|---|

| 1 | Upper Box Body | 1 | 18 | Check Ring | 2 |

| 2 | Middle Box | 1 | 19 | Grease Seal | 1 |

| 3 | Bearing Seat | 1 | 20 | Die | 1 |

| 4 | Forced Filling Oil Cup | 2 | 21 | Cutter | 1 |

| 5 | Reducer | 1 | 22 | Hex Bolt | 1 |

| 6 | Hex Nut | 1 | 23 | Hex Bolt | 1 |

| 7 | Hex Bolt | 1 | 24 | Disc of throwing pellet | 1 |

| 8 | Plus Fit Force Filling Oil Cup | 2 | 25 | Hex Bolt | 1 |

| 9 | Cover of Roller | 2 | 26 | Grease Seal | 1 |

| 10 | Feeding Scraper | 2 | 27 | Dust Cover of Shaft | 1 |

| 11 | Nut | 1 | 28 | Round Nut | 1 |

| 12 | Hex Bolt | 1 | 29 | Lock Ring | 1 |

| 13 | Check Ring for Hole | 1 | 30 | Bearing | 1 |

| 14 | Roller Shaft | 1 | 31 | Grease Seal | 1 |

| 15 | Roller | 2 | 32 | Bearing | 1 |

| 16 | Seal Ring | 2 | 33 | Main Shaft | 1 |

| 17 | Cylindrical Roller Bearing | 4 | 34 | Flat Key | 1 |

As we can see in the chart, the roller-turned pellet mill have different structure with die-turned pellet mill. However, the raw materials still get pressed on the die and shaped in the die holes. Only thing changed is that the die is steady while the roller rolls on it. The structure has its own advantages, which is we can change the roller conveniently. Rollers in different weight create different pressure. We can choose rollers according to the raw materials.

As we can see in the chart, the roller-turned pellet mill have different structure with die-turned pellet mill. However, the raw materials still get pressed on the die and shaped in the die holes. Only thing changed is that the die is steady while the roller rolls on it. The structure has its own advantages, which is we can change the roller conveniently. Rollers in different weight create different pressure. We can choose rollers according to the raw materials.

GEMCO provide quality pellet mills and plants. And we want to be helpful at the same time. If you're interested in our products, please leave us messages and get a quote. If you already have pellet mills, we are happy to solve your problems and also, we offer ISO spare parts. The other parts of the series will be posted next week. If there is any trouble you are experiencing and I haven't talked about, leave a message, I'll give answers in the FAQ in the following days.