How to Improve the Uniformity Of Pellets

Nowadays, the application of small pellet machines has been paid more attention, which is because of that this kind of machine has more advantages and can meet the needs of many industries. High precision technology is used to produce small pellet machines, which can ensure transmission efficiency up to 90%. After the proper treatment, the tooth surface hardness can be improved, and the working efficiency can be increased, and the service life of the parts can be prolonged. In the course of operation, the pellets machine can be quieter, and it also ables to make the overall structure more stable. It can even achieve silent operation, to meet the use of a variety of different environments.

How to make evenly wood pellets

When the user uses the biomass pellet machine to make pellets, the first thing is to want the pellets to be uniform. If the pellets are not uniform, the quality will naturally decline.

Note that the pellets are uniform and have many requirements, first of all, under the same material, the pellets can reach the most uniform state. Some hard materials, such as /panches, sawdust and so on, are easily /poken during pelleitizing, and naturally there will be some small pellets. Strictly speaking, such pellets products have shortcomings in quality.

In the process of making biomass pellets, it is necessary to ensure that the pellets meets the requirement of evenness when using different materials. For example, when wheat straw and tree /panches are used together, it is difficult to make the pellets of the two materials uniform.

How to choose the right pellet mill manufacture

In the pellet manufacturing industry, the /pand biomass pellets is due to a variety of technical improvements, rather than simply crushing materials. Different materials, density calculation methods are different, so this kind of pellets in use will really ensure its pellets uniformity. So you should be careful when you buy this kind of product. Although some manufacturers' products look low in price, they can't guarantee the uniformity of pelletizing, so low price /pings about low quality of work. However, many manufacturers in the pellet machine manufacture market do not meet this requirement, because the concentration of pellets under different materials is different, which often results in the differences of pellets. Some manufacturers simply refit the pellets into a pulverizer, which can not meet the requirements of uniform pelletizing in use.

GEMCO offers you help

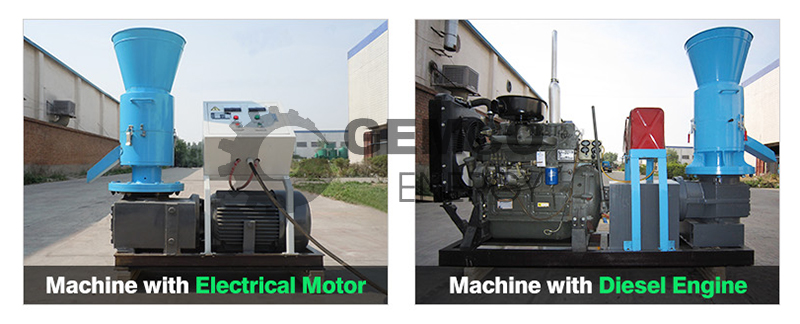

The choice of high quality material for the bearing of mechanical equipment such as GEMCO pellet mill machine greatly enhances the strength of the machine and the quality of the product.

In the process of production and processing, the GEMCO pellet press machine can reasonably control the production cost. The purpose of this kind of machine is to apply it to pelletizing of sawdust, which can /ping into play higher working efficiency, improve machining precision and meet the needs of different enterprises.

The above advantages are unique to small pellet machines. The GEMCO pellet machines are designed by a unique process to ensure a more perfect overall structure, and can play a more diversified function in the process of practical operation. We can choose according to our own needs to ensure that we can meet the application standards and make economy better. Please leave us messages below to get in touch.