9 Tips on How to Use Biomass Pellet Mill Properly

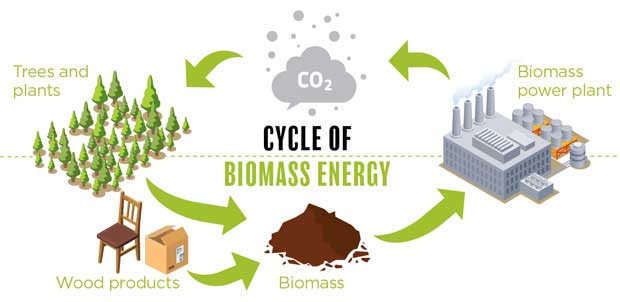

Biomass pellet mill can process the wastes of agriculture and forestry such as sawdust, straw, rice husk, bark etc. Through pretreatment and machining, the biomass materials can be formed into high-density pellets, which is an ideal alternatives for burning coal and oil. Biomass pellet fuel can save energy and reduce emissions, it achieves both economic and social benefits. Biomass pellet is a kind of clean and renewable energy.

GEMCO is a leading manufacturer of biomass pellet mill machines located in Henan, Anyang, China's famous ancient capital. Our company has a strong technical research and development team, first-class factory and production facilities, advanced testing equipment, complete quality inspection system standard and perfect after-sales service. Our company produces biomass pellet mill, biomass pellet plant and biomass pellet production line.

So, what is the proper way to use biomass pellet mill? Let's take a look at this:

- The long-term-operation biomass pellet mills and plants should be fixed on cement foundation. The biomass pellet mill and its motor should be installed on the seat made of angle iron if the working place is constantly changed. If the biomass pellet mill use diesel power, the power of both machine should be matched, namely the power of diesel engine should be slightly bigger than the crushing machine in the biomass pellet production line, and make the pulley groove of this two consistent, pulley end on the same plane.

- After the installation of the biomass pellet mill, check the fastening conditions of the fasteners and tighten them if they are loose.

- Check whether the belt tightness is suitable or not, and whether the motor shaft is parallel with the biomass pellet mill shaft or not. And adjust them as the products brochure says.

- Before starting the biomass pellet mill machine, turn the rotor by hand, and check the tooth claw hammer. If the rotor operation is flexible and reliable, and there are no collisions in the shell, rotor rotates to the direction as the arrow on board pointed, and the biomass pellet mill lubrication are in good condition, then, you can put the biomass materials in now.

- Do not change the pulley, in case the speed is too high to cause explosion, or the speed is too low to affect the work efficiency.

- After the pulverized platform is started, it should be idled for 2, 3 minutes, and if there is no abnormal phenomenon, then you can perform the following operations.

- In the work, we should pay attention to the operation of the biomass pellet machine. The feeding should be even, so as to prevent the blocking of the feed hopper. And do not overload for a long time. If there is vibration, noise, high temperature of the bearing and body, or material blowing out, you should stop the biomass pellet mill and inspect the machine immediately. The biomass pellet machine can continue to work after troubleshooting.

- The crushed material should be carefully checked so as to avoid the accident caused by copper, iron, rock and other hard objects in the crushing chamber.

- The operator should not wear gloves, and should stand on the side of the biomass pellet mill when feeding, so as to prevent the bouncing debris from injuring the face.

GEMCO biomass pellet mill achieves reasonable design, exquisite material chioce, elegant appearance, reliable quality, and simple operation. Our biomass pellet mill for sale now features small footprint, low energy consumption and high cost performance. GEMCO can customize the biomass pellet processing equipment and biomass pellet production process for the users according to the users' raw material condition. Besides the biomass pellet mills and plants, our company provides free business consulting services related to biomass pellet production and application.