Comparative Analysis of Ring-die Pellet Mill at Home and Abroad. Part 1

This article will be talk about ring-die pellet mill at home and abroad. The pellet mill abroad will be talked in the next part cause there are a lot of excellent brand. Compared with which, ring-die pellet mill is not so advanced but has its own superiority. The advantages mentioned in the article, are not just about GEMCO, but a general view of Chinese ring-die pellet machine.

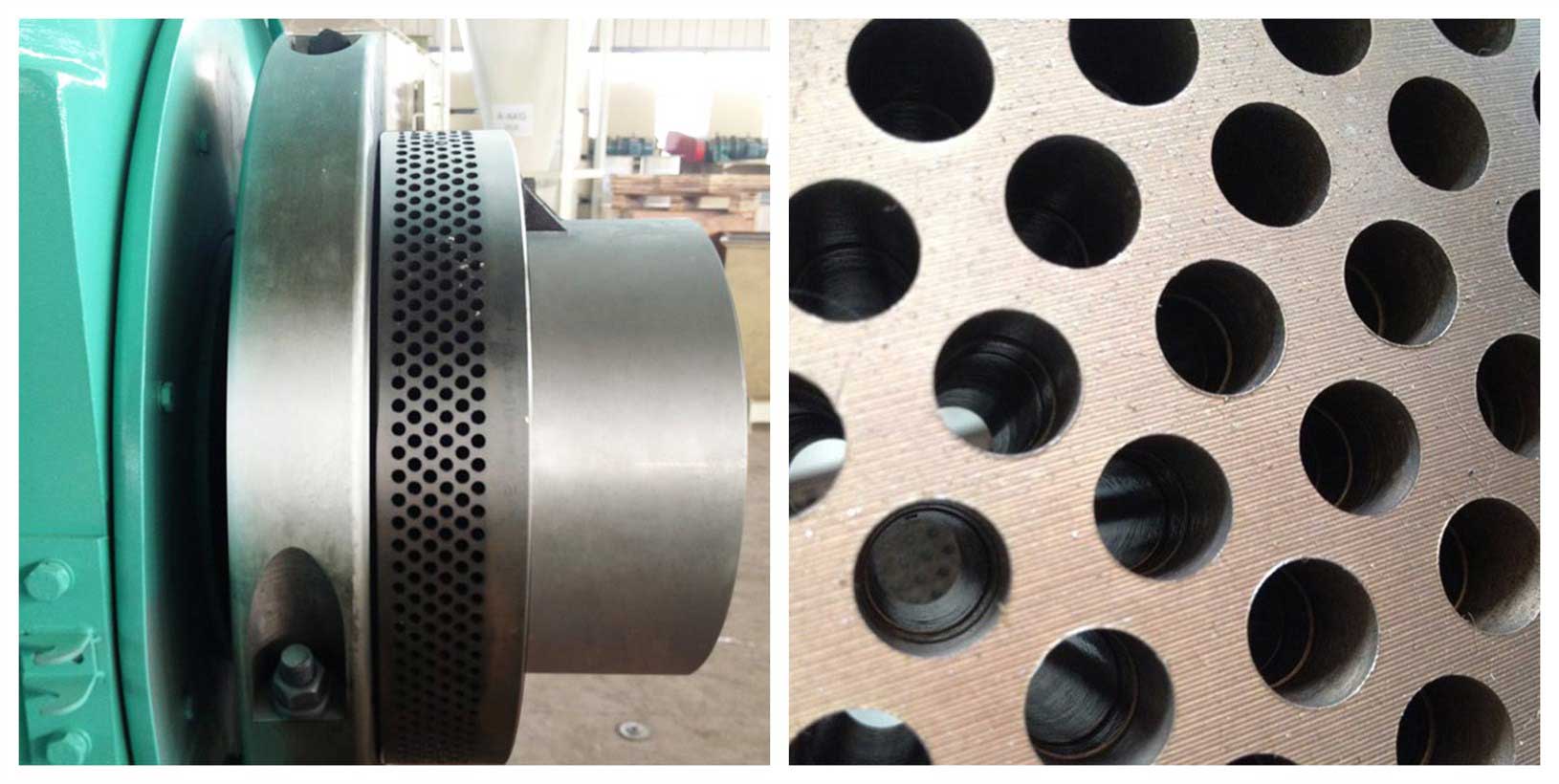

Ring-die pellet mill structure

Ring-die pellet mill equipment and its process supporting equipment are mainly formed by pellet mill machine, modulator, aging machine, dryer, cooler, crusher, classifying screen and bunker activation device etc. In accordance with the different process of different raw materials, the equipment can be customized.

Since the Sizer company, England developed the first pellet mill in 1910, the manufacturing technology and molding theory of pellet mill machine have been developing rapidly.

At present, the common pellet mills are flat-die pellet mill and ring-die pellet mill. According to the kinetic characteristic, they can be divided to die-turned pellet mill and roller-turned pellet mill. According to the compound mode of ring, die and roller, they can be divided to three-roller, two-roller, big-roller, small-roller double loop mode ring-die pellet mill, flat-die straight-roller pellet mill and the twin cone roll pellet mill.

Ring-die pellet mill are mainly formed by feeder, modulator, pelletizer, adjust parts and lubricating system.

Chinese ring-die pellet mill advantages

The classic structure of ring-die pellet mill in domestic is as follows:

The advantages of ring-die pellet mill are:

- Advanced double-motor step-by-step flexible-drive system, stable and reliable.

- The key parts adopts high-quality imported components, long service life, low maintenance cost.

- International standard manufacturing, stable and reliable performance.

- Clamp type modulator and DDC Conditioner can be configured as optional.

- Alloy structural steel forging spindle, goog strength and toughness.

- Wide application in making high-quality biomass pellet.

Ring-die pellet mill is an important kind of biomass pellet mill machine. The research on ring-die pellet mill structure technology optimization, has its great significance. The research on ring-die pellet mill aboard mainly concentrate on mechanism analysis and experimental study. The research in domestic mainly concentrate on the introduction, design of products and the process influence on pelletizing. As for the product structure, the ring-die pellet mill is excellent in performance and category. The ring-die pellet mill domestic is not as advanced as the foreign ones, but features quality material, affordable price and thoughtful service.

GEMCO provide quality pellet mills, both ring-die and flat-die. Recently, the small wood pellet mill is our most salable products in the international market. But ring-die pellet mill still has its own place in the pellet mill world. Ring-die pellet mill can process hard raw materials like wood chips, log, bark etc. It is highly suitable for large scale pellet production. Now our company has set ring-die pellet mill production line for many clients which can produce pellets from 1ton/h to 32ton/h. If you need ring-die pellet mill, please click here or leave message for quotation and details. Thanks for reading, the analysis about other brand pellet mill machine abroad will be posted in the following days.