Comparative Analysis of Ring-die Pellet Mill at Home and Abroad. Part 2

This article will be talk about ring-die pellet mill at home and abroad. The classic pellet mill brand abroad are talked in this part including UTM, CPM, SW etc. Compared with which, Chinese ring-die pellet mill is not so advanced but has its own superiority. The classic ring-die pellet mill abroad:

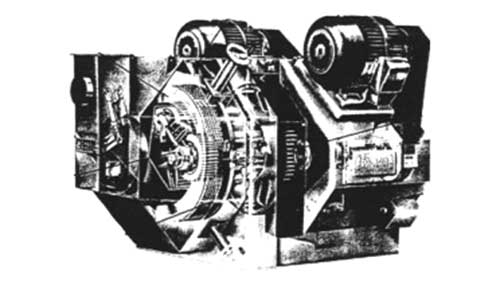

Three-roller ring-die pellet mill

Three-roller ring-die pellet mill is a typical pellet mill model of UTM company, England. A lot of pellet mill manufacturers produce similar products in Chinese and other countries. This pellet mill can be divided into die-turned and roller-turned. The crown brand three-roller ring-die pellet mills produced by UTM all adopted synchronous belt transmission, in which, the 350B model adopted double motor synchronous toothed belt drive while the other models adopted double motor tripod, synchronous toothed belt secondary transmission.

UTM pellet mill features:

- Adopted three-roller structure, equipped with a stock guide, good feeding and pelletizing effect.

- Adopt the synchronous toothed belt double motor drive, even workload, high transmission efficiency, low noise. The machine shape is beautiful, long, wide, high proportion is symmetrical.

- Adopted the friction plate hydraulic overload protection device to ensure safe operation, and the reset is convenient.

- Equipped with automatic lubrication system, make sure the machine is working properly.

- Outside the ring-die, there are 3 cut knife, which is conducive to uniform particle size.

- The body and frame are treated with steel plate after welding to eliminate stress, simple structure and beautiful modelling.

- Long service life with less toothed belt and main bearing, 3-40 thousand hours and 5-8 years respectively.

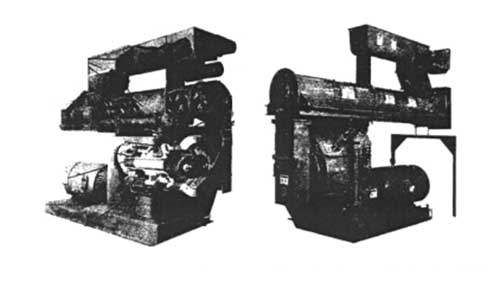

Gear driven type ring-die pellet mill

The gear driven type, represented by CPM products. Single-machine triangle belt drive type, represented by Buhler products. Double motor triangle belt drive type, represented by Munch products. There are many kinds of similar products produced in the world, but the principle and structure are basically the same.

CPM pellet mill

CPM pellet mill adopts the helical gear reducer casing transmission device, speed reduction gear box can achieve two-speed exchange through the manual transmission. The ring-die is fixed on the big gear transmission hollow shaft and roll, and the roller is fixed on the solid shaft fixed with a brake device, this is die-turned pellet mill. The ring-die adopted triplasy ring-die clip to get fixed, easy to attach and detach. And the pellet machine is equipped automatic circulation lubrication system, using more safety.

SW pellet mill

SW produce two-roller and three-roller pellet mill, the transmission mode is gear type, the speed can be divided into double speed and single speed. The large-scale pellet mill adopted forcing feeding, to ensure uniform and stable feeding.

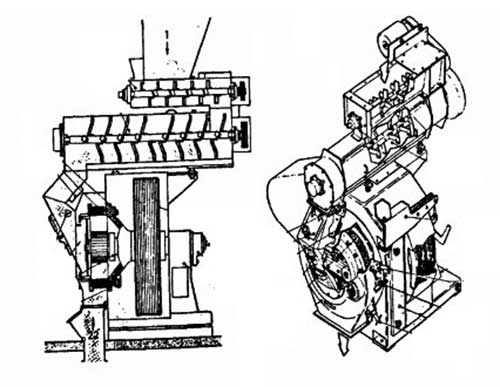

Buhler pellet mill

Bulhler pellet mill adopted double pressure roll, ring mode, single motor triangle belt transmission structure. High unit production efficiency, low operating cost, simple structure, easy operation and maintenance. Automatic lubrication and automatic control can be implemented conveniently. By a single motor drive, hollow shaft, ring die, spindle, roller and big belt transmission assembly, and the tension of belt transmission by spindle end cantilever support, such as high load bearing, and belong to the partial load condition. The design, checking and assembly requirements are high.

Munch pellet mill

Munch produces ring-die pellet mill and tapered roller flat-die pellet mill. Ring-die pellet mill has the similar structure with English UTM. Munch ring-die pellet mill adopted v-belt drive, the width of the large pulley is wider. Cast iron casting whole frame, the whole machine weight is heavy, but the operation is stable, the noise is low, the inertia effect of large pulley is beneficial to energy saving. The fixed structure is appropriate to use the triplasy ring-die clip. For example, to adopt the bolt fixed structure, then the unilateral operation can prolong the service life of the die.The system can realize automatic lubrication and automatic control.

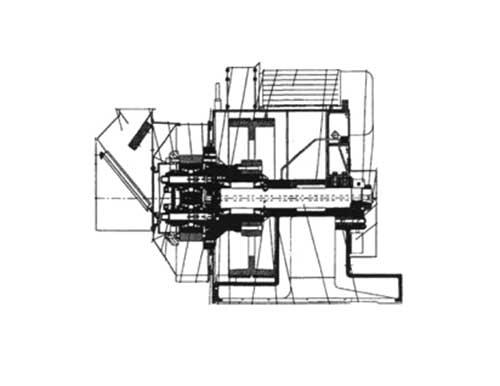

PCI new pellet mill (roller-turned)

PCI pellet mill is a patterned product of PCI, America. The pellet mill adopted closed steam pressure pelletizing system. From the screw feeder outlet to the pellet mill ring moulding chamber is under positive pressure, steam pressure should be controlled at 20-70kPa. Material seal can be formed when the thickness of the inner material layer reaches 3mm. The whole process of material flow and granulation process is equivalent to a long time closed pressure modulator (1.5-30s), with good quality control effect, and the granulation temperature is between ordinary pellet mill and expansion and expander. Adopt moving roller ring die, roller combination, single belt or gearbox transmission. Simple structure, convenient operation and low cost of pelletizing. The grain cutting device consists of motor drive, cutting tool holder, cutter, etc. The motor is installed on the operation door.

GEMCO provide quality pellet mills, both ring-die and flat-die. Recently, the small wood pellet mill is our most salable products in the international market. But ring-die pellet mill still has its own place in the pellet mill world. Ring-die pellet mill can process hard raw materials like wood chips, log, bark etc. It is highly suitable for large scale pellet production. Now our company has set ring-die pellet mill production line for many clients which can produce pellets from 1ton/h to 32ton/h. If you need ring-die pellet mill, please click here or leave message for quotation and details. Thanks for reading, the analysis about other brand pellet mill machine abroad will be posted in the following days.