How to Build A Cat Litter Pellet Making Machine Line

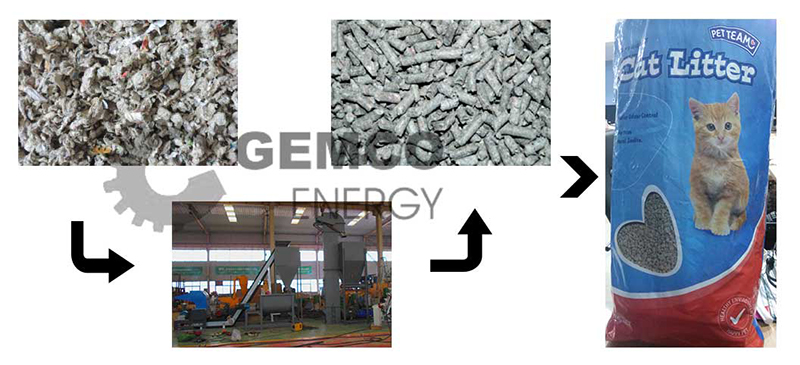

When we talk about pellets, most of us may think of wood pellets or other kinds of biomass pellets made of agriculture wastes. However, in fact, pellets can do more things than you think. Recently, GEMCO set a cat litter pellet production line in New Zealand. Our clever clients turn waste paper into cat litter with our pellet mill machine. Cat litter is important for cat owners. Good cat litter features strong water absorption and odor removing. Pellet is an ideal form of cat litter and it is especially easy to clean up.

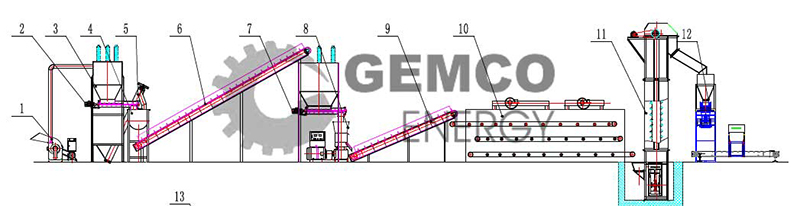

Cat litter pellet production line we offer

There is a list of the pellet press machine and other pellet making equipment we’ve used to build the pellet production line. Check the chart and get to know the pellet making machine and pellet price.

| NO. | NAME | TYPE | QUANTITY | POWER(KW) | MAIN SPECIFICATION | PRICE(USD) | ||

|---|---|---|---|---|---|---|---|---|

| SINGLE | TOTAL | SINGLE | TOTAL | |||||

| 101 | HAMMER MILL | FSP420B | 1 | 7.5 | 7.5 | for paper | 860 | 860 |

| 102 | SCREW FEEDER | LS160 | 1 | 0.75 | 0.75 | with arch breaking device to avoid jamming | 1095 | 1095 |

| 103 | HOPPER | 0.5m³ | 1 | 1185 | 1185 | |||

| 104 | MIXER | 9HWP250 | 1 | 4 | 4 | 1405 | 1405 | |

| 105 | LOADER | GX160 | 1 | 1.5 | 1.5 | 1285 | 1285 | |

| 106 | BELT CONVEYOR | B500×6.7米 | 1 | 3 | 3 | 2390 | 2390 | |

| 107 | SCREW FEEDER | LS160 | 1 | 0.75 | 0.75 | with arch breaking device to avoid jamming | 1095 | 1095 |

| 108 | PELLET MILL | ZLSP300B | 1 | 22 | 22 | 2095 | 2095 | |

| 109 | BELT CONVEYOR | B500×3.8 | 1 | 3 | 3 | 1570 | 1570 | |

| 110 | DRYER | 1000×12000 | 1 | 4.5 | 4.5 | Optional | 14720 | 14720 |

| 111 | BUCKET ELEVATOR | TD160 | 1 | 3 | 3 | 2270 | 2270 | |

| 112 | PACKING MACHINE | 1 | 1 | 1 | optional | 5000 | 5000 | |

| 113 | ELECTRIC SYSTEM | |||||||

| ELECTRIC CABINET | 1 | 2375 | 2375 | |||||

| CABLES | connecting from controlling cabinet to each equipment | 3100 | 3100 | |||||

| Total( USD/FOB ) USD40445 ; USD20725 if not including dryer and packing machine . | ||||||||

| MEMO: | ||||||||

| 1 | not including installation fee | |||||||

| 2 | platforms or equipment brackets and connecting devices and materials need to be supplied by users | |||||||

| 3 | paint( using for installation materials ) need to be supplied by users | |||||||

| 4 | air compressor need to be supplied by users | |||||||

| 5 | validity of time of price : 2 months | |||||||

Pellet production line dryer for cat litter

Main specification

- Materials:wet cat litter

- Original moisture:35-40%

- Final Moisture :5-8%

- Capacity :125kg/h

- Shape of material : pellets with diameter 5mm

- Heat source:electrical heating

drying system

According to the demands of the clients, we set a drying system in this pellet production line. This kind of the band dryer/net belt dryer can be continuous production in batches. The main working principle is as follows: the materials are putting onto the band/belts inside the drying case, the band/belts with the wet materials will be moved back and forth inside the drying case, the hot air blow through the wet materials and bring the steam/vapour out from the holes of discharging humidity. The width of drying case is 1 meters, 0.8 meters for band/belt, total length 12 meters, total three layers.

Check the list to see the equipment in the pellet production line drying system.

| NO. | NAME | SPECIFICATION (mm) | POWER (KW) | QUANTITY | MEMO |

|---|---|---|---|---|---|

| 1 | hopper | 1pc | Q235 | ||

| 2 | dryer | 1000×12000 | 1set | Double layers, Q235 , Using heat preservation materials between layers | |

| 3 | Band/belt | Width 0.8 meters | 72 meters | Q235, three layers | |

| 4 | motor | Electromagnetic speed-regulating | 3 | 1 set | Electromagnetic speed-regulating to adjust the speed of band |

| 5 | Air fan | 1.5 | 2sets | Removing the humidity out | |

| 6 | Electric heating | 65 pieces | 1set | Made of Stainless steel ,the temperature can be adjusted | |

| 7 | e-cabinet | 1set |

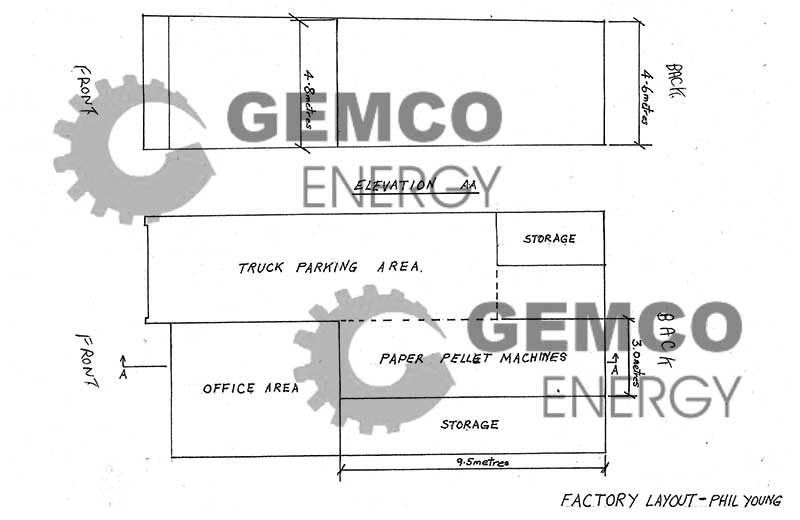

Now this pellet production line is working well in New Zealand and our client is bringing in from this pellet making machine project. GEMCO pellet making machine is quality and reliable. We lift your business. More information about our products, please contact us by leaving messages below. GEMCO, at your service.